What Is Hypochlorous Acid?

Hypochlorous acid is a weak acid that our bodies actually produce naturally, and it can also be found in the human immune system – our white blood cells produce it to destroy pathogens. When manufactured for industrial use, it’s made, for example, by electrolysing a simple saltwater solution. It should be noted that none of the raw materials or packaging components used in the manufacture of AGMA Products are derived from Animal or Human origins.

Despite being “weak” as an acid, it is extremely strong as a disinfectant, outperforming many commonly used agents.

What’s the difference between hypochlorous acid (HOCl) and hypochlorite (OCl⁻)?

Hypochlorous acid (HOCl) and hypochlorite (OCl⁻) are two forms of the same kind of disinfecting chemical, but they work a little differently. Hypochlorous acid is arguably the more effective form—it kills germs much faster and with other applications including on skin, wounds, and food surfaces, usually at lower concentrations than those traditionally used for cleanroom surface disinfection.

Hypochlorite, on the other hand, is the stronger-smelling, more irritating form found in regular bleach. It works as a disinfectant too, but not as well as HOCl and it can be harsher on skin and surfaces. HOCl shows up in more acidic (pH 5-6) solutions, while hypochlorite forms in more alkaline (higher-pH >7.5) solutions like standard bleach.

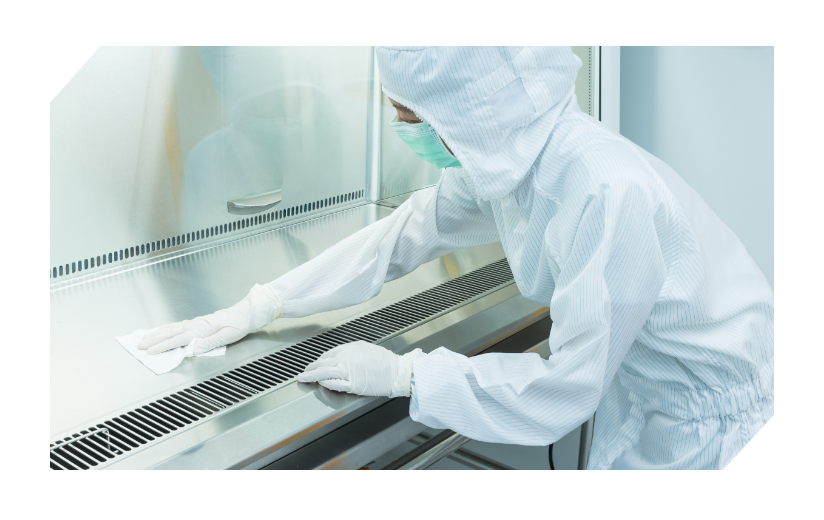

Why Hypochlorous Acid is Perfect for Cleanrooms

- Easily Penetrates Microbial Cells

Being electrically neutral, Hypochlorous acid (HOCl) can easily diffuse through microbial cell walls. Inside the cells, it rapidly destroys them by oxidising their enzymes and DNA. - Kills a Wide Range of Contaminants

HOCl is highly effective against bacteria, viruses, fungi, spores, and potentially even biofilms. This broad effectiveness is essential in cleanrooms used for large pharmaceuticals, biotech and other industries where reducing contamination is vital. - Works fast

Time matters in cleanrooms. HOCl kills microbes in minutes, depending on the concentration and the type of organism. Faster kill times help improve efficiency and reduce downtime between cleaning cycles. - Cleanroom surface compatibility

Unlike bleach, HOCl is non-corrosive if all residue is removed once the contact time has been achieved. It can be safely applied to a range of materials used in cleanrooms, including stainless steel, aluminium and copper. This makes it ideal for environments where material compatibility is critical. - Non-hazardous

It is classified as non-hazardous for both transport and storage, making it easier to maintain regulatory compliance in controlled settings. - Leaves No Harmful Residue

HOCl is VOC-free and leaves no harmful residues. Residue can interfere with cleanliness and production processes. However, depending on the raw materials used to manufacture hypochlorous acid, some minimal residue may remain on surfaces. You should always follow manufacturers instructions on wiping down procedures. - Fits Cleanroom Protocols

HOCl integrates easily into routine cleaning procedures. It can be used in rotational disinfectant programmes, daily sanitisation, post-maintenance cleaning, and sterile suite maintenance. Its speed, effectiveness, and low residue in nature make it a strong complement to other cleaning agents like Isopropyl (IPA) 70% or Denatured

Ethanol (DE) 70%.

Key Takeaway

AGMA’s Sterile Zyceine, a hypochlorous acid (HOCl) cleanroom disinfectant, combines powerful antimicrobial action with material compatibility, and process efficiency. Its rapid penetration of microbial cells, ability to eliminate a wide range of contaminants, and minimal residue make it an excellent choice for cleanroom applications.

Note: AGMA’s Sterile Neutral Detergent is ideal to prepare surfaces prior to disinfecting. After applying Zyceine for the approved biocidal contact times, it is important to rinse the surface off with Sterile WFI quality water and wipes.