Top tips for incorporating a sporicidal disinfectant in your contamination control strategy

Cleanrooms are susceptible to different types of contaminants, from residues to different particles and microbes. In healthcare especially, any of these could potentially compromise product integrity and patient safety. But of all contaminants, spore contamination is the most difficult to tackle. This blog will delve into the sticky issue of spore contamination, both bacterial and fungal, look at why and how you should incorporate a sterile sporicide into your contamination control strategy, and run through important considerations and best practices.

The challenge of tackling spores

So why do spores present such a problem?

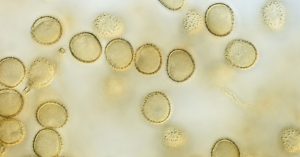

Small, dormant and resilient, many different types of spores exist in nature, and our air and soil is full of them.

Spores are tiny, usually single-celled. Generally dormant, they are neither actively growing nor dividing. As small structures with minimal metabolic activity, they are more resilient than vegetative cells.

Many fungi, algae, protozoa, and some plants form spores to spread and reproduce. They can be well-adapted to survive in adverse conditions until they find a suitable environment to germinate.

But with bacterial endospores, that resilience is much more dramatic. Certain bacteria sporulate, not to reproduce, but as a survival mechanism. They form highly resistant endospores that can survive in extreme conditions that would be impossible for other forms of life.

This means the bacteria, in its dormant form, can withstand extreme conditions including heat, radiation, desiccation, and traditional chemical disinfectants. As explored in our previous blog, viable spores have been found in melting permafrost, trapped in amber, and even unintentionally left by astronauts in space. Bacteria can survive in a dormant form for millions of years. Then when conditions improve, viable spores can reactivate.

What does this mean for contamination control?

Killing vegetative microbes is one thing, eliminating spores is another.

This persistence and resistance to disinfection means controlling bacterial and fungal spore contamination in pharmaceutical cleanrooms and hospitals is vital.

Processes for manufacturing sterile products have to take this high level of resistance into account.

Annex 1, which provides detailed requirements for the manufacture of sterile medicinal products, specifies the use of a sporicide to minimise the risks of contamination.

Since bacterial endospores can withstand many disinfectants that would kill vegetative cells, it is necessary to use sporicides specifically designed to destroy spores rapidly and effectively.

Annex 1 defines a sporicide in this way:

“An agent that destroys bacterial and fungal spores when used in sufficient concentration for specified contact time. It is expected to kill all vegetative microorganisms.”

This means in your contamination control strategy you need to incorporate a sporicide with validated efficacy, proven application methods, and specified contact time.

Crafting your sporicidal contamination control strategy

Annex 1 specifies the need for a written, formal contamination control strategy.

Operators of healthcare and pharmaceutical cleanrooms have to develop robust contamination control strategies with clear cleaning and disinfection protocols.

This means implementing a validated cleaning agent, disinfectant and sporicide as part of a regular cleaning schedule, including routine cleaning, disinfection, and deep cleaning of critical surfaces and equipment.

Protocols should outline step-by-step procedures for cleaning different areas of the cleanroom, including equipment, surfaces, and floors. Specify the frequency of cleaning, the type of cleaning agents to be used, and the methods for application and removal.

Here are some important things to consider to make sure your contamination control strategy is in line with Annex 1 guidance and effectively protects against spore contamination.

Use a sporicide with validated efficacy

Use a sporicidal disinfectant with independently validated microbial efficacy.

You want proven log-reduction so you can be confident it is effective against contaminants.

For example, AGMA’s sporicide Zyceine has a proven fungicidal efficacy of greater than a 3-log reduction in 2 minutes, and a yeasticidal efficacy greater than a 4-log reduction in 2 minutes.

Use sterile cleaning agents

You don’t want your disinfectants themselves to be a potential source of contamination. That’s why you should select a product that is itself sterile.

Section 4.35 of Annex 1 specifies that, “disinfectants and detergents used in grade A and grade B areas should be sterile prior to use.”

This means the sporicidal product should itself have been manufactured in sterile conditions.

Specify the method of application

Remember the Annex 1 definition of a sporicide? It “destroys bacterial and fungal spores when used in sufficient concentration for specified contact time”.

Your disinfection protocol should be very clear on the appropriate application method. Your method must apply a sufficient concentration of the sporicide for the specified contact time, and ensure that cleaning methods are appropriate for the surfaces being cleaned, taking care to avoid damage or residue buildup.

For this reason, wipes impregnated with alcohol or biocides are highly effective where there is a need to disrupt the surface biofilm, rather than the use of a trigger spray. Wipes also save time, and avoid the need for both a spray as well as a dry wipe. Wipes are also preferable in circumstances where it is important to avoid introducing liquid spray into the air surrounding a critical product filling point.

Finding the right sporicide—the AGMA solution

Sporicides are indispensable for controlling the contamination risk from super-resistant bacterial spores.

However, using them can come with its challenges.

As we’ve explained, standard disinfectants can’t necessarily penetrate or damage a spore’s protective layers and resilient internal components. Sporicides are especially designed to overcome these robust defences. Cleanroom sporicides are typically powerful oxidising, or sometimes alkalising agents that can disrupt vital structures within the spore and damage its DNA. But being so reactive, they can be chemically unstable with a very limited shelf life, and they can also be corrosive to cleanroom equipment and surfaces.

We developed a solution to this challenge with our award-winning sterile sporicide Zyceine.

Zyciene leaves minimal residue and is much less corrosive to metals than other disinfectants. This reduces the risk of damage to expensive equipment.

What makes Zyceine really unique is its two-compartment design that keeps the compounds separate and completely stable until you activate it right before use, prolonging its efficacy and shelf-life far beyond alternatives on the market.

It’s never been easy to eliminate spores, that’s for sure, but these innovations are making it easier and more cost-effective to incorporate sporicides in your cleanroom cleaning and disinfecting routine.

You can read more about Zyceine in our blog here.

Related products

| Sterile Zyceine in WFI High Quality Wipes 68 GSM | Sterile Zyceine in WFI 200ml Liquid Pouch | Sterile Zyceine in WFI 1L Liquid Pouch |